It may seem counterintuitive to expect a designer to plan his product to be self destructive, but it is precisely because we have not taken disposal into account for so long in industry, that our waste situation today is unmanageable.

As the importance of biodegradability became more and more imperative, designers started to look at the entire life cycle of products – starting from the cradle, when it is born to the grave, where it will go when it is no longer usable. This further went on to the concept of cradle to cradle, which also involves the designer to look at what will happen to the materials the product is made of, after it is thrown away.

And this is where they start designing the product for destruction – disassembly rather.

When we can make a product easy to put together and as easy to pull it apart, it reduces the effort involved in recycling each of the individual materials involved in making it. Products using a combination of materials, for eg a shoe that uses fabric and rubber, require the seams to be intelligently designed to enable such disassembly.

It sounds a bit like Lego, but perhaps this may be the key approach to making recycling a financially viable option for the manufacturer.

The guidelines for Designing for Disassembly (DFD) involve several more technical features but in principle there are a few basic changes in the way DFD products are to be designed. These come from a deeper understanding of the steps involved in recycling.

A product needs to be disassembled, then cleaned, sorted. After this its elements may be partly reused and upgraded to be reassembled.

For a material to be recycled it first has to be separated from the other materials, sorted and then reprocessed completely to be usable again.

Designing for disassembly guidelines broadly recommend:

1. Using fewer materials and maximising each material.

2. Eliminating the use of glues and fasteners and moving into snap fit modes.

Some of the most difficult materials to recycle are those that have several layers fused together such as Tetrapak or mettallised film. This is what makes them non biodegradable too. The amount of effort that goes into separating paper from plastic from aluminium in a Tetrapak container makes it virtually impossible to do it in a profitable way.

So the bond between materials and the connections become a very crucial element of designing for disassembly.

3. Therefore DFD recommends that one avoids the use of non recyclable materials altogether, and eliminates the use of incompatible laminated and non seperable materials.

Does DFD make products less durable or more vulnerable to breakage?

This is where the design challenge would lie. The durability of a DFD product may not be compromised even if it is being designed to come apart more easily. While there may have to be a higher tolerance for deterioration in DFD, safety considerations during disassembly cannot be ignored.

Recycling may be done either manually or mechanically depending on what the product needs. In both cases the hazards to the person doing the recycling has to be minimised and the toxic effects of recycling managed appropriately.

In the field of construction and architecture, DFD is now evolving different ways of planning a building altogether. Randy Croxton who runs the Croxton Collaborative and was invited to design a building in this manner by the University of Florida summarises the approach in three main principles

1. Look for ways not to build; which means that they try to find out of the box solutions to functional requirements that don’t create enclosed built space.

2. Avoid glued and composite materials, so that retrieval of materials can be done at full value.

3. And thirdly, avoid demolition as far as possible.

The ultimate vision of DFD in building deconstruction would be that elements could be packaged and sent away for reuse almost as neatly as they arrived when the building was being first put together. Architects would be expected to come up with dismantling plans and conduct deconstructability reviews!

Destruction and disassembly then are no longer seen as a disadvantage and a burden, but one more outlet for innovative and creative design.

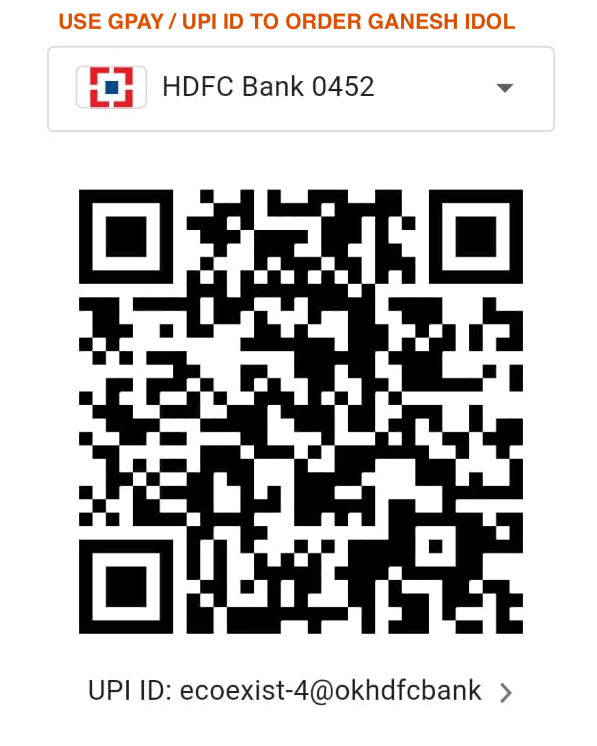

These articles form a series in the Green Idea campaign called The Beauty of Recycling conducted by eCoexist and Studio Alternatives and sponsored by the Government of Maharashtra, Environment Department. They aim to raise awareness about the aesthetic and financial potential of recycling. To read more visit www.beautyofrecycling.in